With its fast printing speed and high throughput capabilities, 3D printing SLA service offers rapid turnaround times, accelerating product development cycles and reducing time-to-market. Compared to traditional manufacturing methods, which often involve lengthy lead times for tooling and setup, SLA printing allows for quick iteration of designs and on-demand production of prototypes. This agility enables businesses to test and validate concepts rapidly, iterate designs efficiently, and bring products to market faster, gaining a competitive edge in dynamic industries where speed and innovation are paramount.

Of late, Huilichuang has emerged as a renowned supplier of 3D printing SLA services in the manufacturing sector. We have spent many years and applied cutting-edge technological innovations to ensure our customers get fine-tuned machines parts. Through this service, we offer unmatched truth regarding details thus giving assurance to businesses when making complicated objects for various purposes. For companies that want to advance their manufacturing abilities, Huilichuang is the leading choice since it highly values quality and creativity.

One of the most challenging aspects is merging new technologies into existing workflows, but having Huilichuang’s 3D printing SLA services makes it a smooth one. By understanding clients’ individual needs and creating custom-made solutions that blend easily with their production systems, our experienced team works closely with them. Prototyping, tooling or end-use parts are some of the areas where we provide full support during implementation of SLA technology. We take you through from the starting point when you contact us until we offer maintenance and other assistance as you proceed to additive manufacturing process thus making Huilichuang your best partner in this venture. For a successful integration project, trust on our competence and commitment to customer desire.

At Huilichuang, we appreciate the importance of prototyping in product development. Our 3D printing SLA service offers a speedy and cost-effective avenue to convert idea into actuality. We aid designers and engineers in doing quick proofs of concepts, speed up iterations and perfect those using advanced SLA technology. For that reason, with our help, organizations can accelerate their time to market so as not lag behind competitors. From the start of an idea until it is ready to be launched in the market Huilichuang prides itself on being there through different stages for its clients.

Huilichuang realizes how vital it is to be able to customize every project. Our SLA 3D printing service offers custom-made solutions that meet specific requirements of our customers. We cooperate with our clients in close proximity to fulfill their customized wants such as developing personalized models, improving design durability and meeting special needs. Huilichuang can adapt its projects according to the customer’s current need because it knows about additive manufacturing better than anyone else does. Design concept to final production – Huilichuang takes pride in giving clients tailored made solutions for them to realize their vision.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

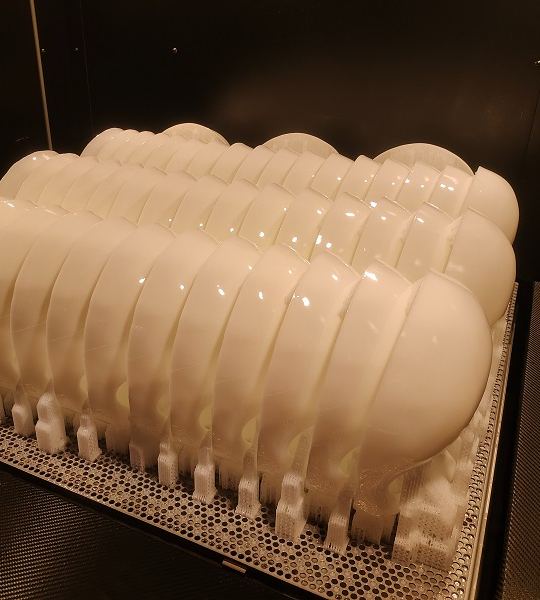

3D printing SLA service stands out for its high resolution and exceptional surface finish, making it ideal for producing intricate and detailed parts with precision.

Parts produced by 3D printing SLA service often exhibit superior accuracy, as the process allows for the creation of complex geometries with minimal distortion or deviation from design specifications.

Turnaround times for orders with 3D printing SLA service vary depending on factors such as part size, complexity, and quantity, but generally offer fast lead times compared to traditional manufacturing methods.

Yes, 3D printing SLA service supports a variety of resin materials, including standard, engineering, and specialty resins, enabling versatility in meeting diverse application requirements.