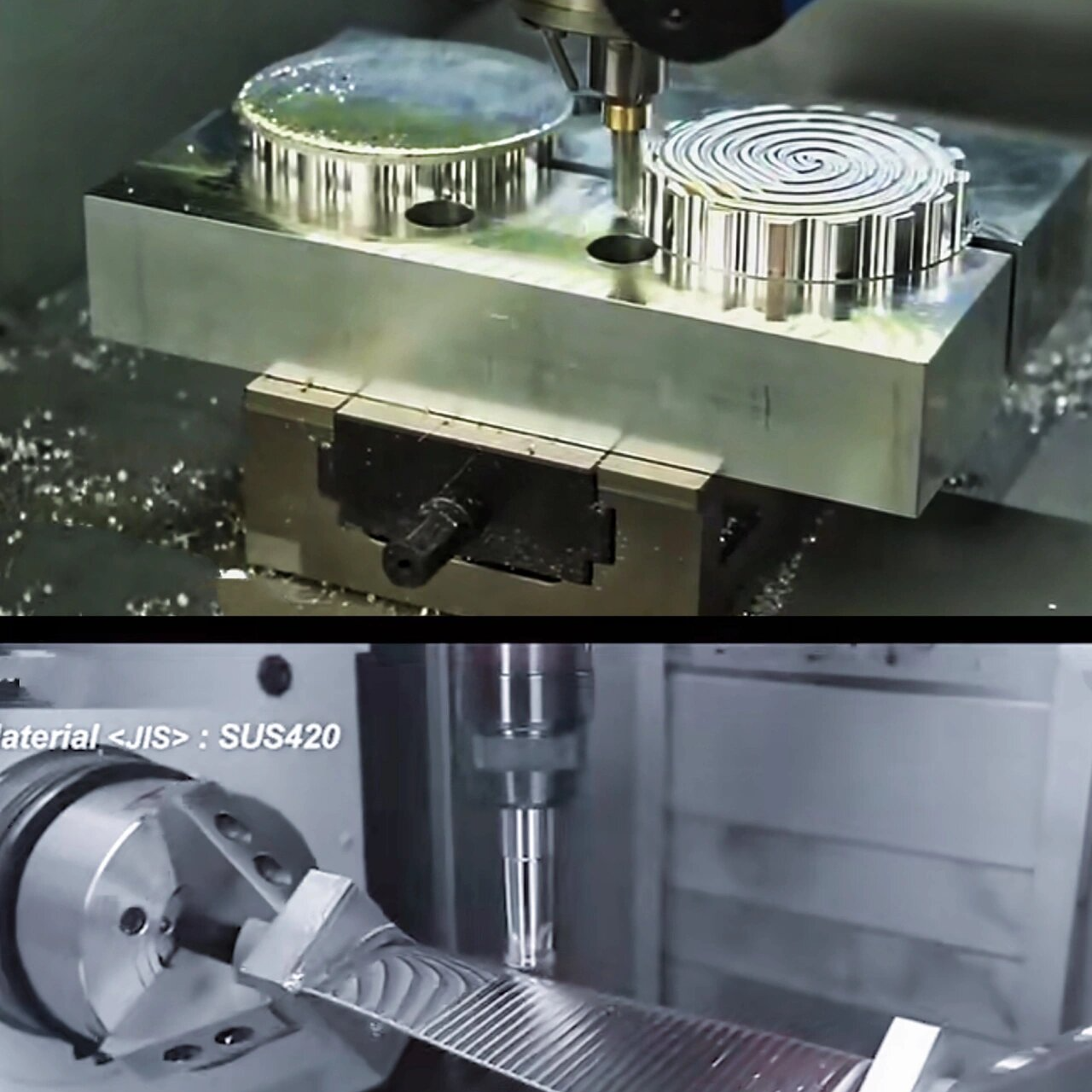

CNC, or Computer Numerical Control machining services, as their name suggests are computer-controlled machines that make detailed components using various materials like metals, plastics and composites. There is a wide array of advantages that come with this advanced technology in manufacturing including accuracy, repeatability and efficiency. The cutting tools’ movement among other machinery parts in CNC machining are directed by computer program which makes it possible to achieve highly detailed designs and complicated ones with limited human involvement. This means that prototypes can be produced alongside custom parts mass production.

In the case of CNC machining service provision, there are some tolerances that can’t be met with conventional machining techniques while still achieving complex geometries. The ability to machine parts for these industries means an availability of many different applications like electronics, automotive, aerospace and medical devices. Moreover, fast turnaround times as well as cost effectiveness and the ability to work on many kinds of materials have made CNC machining services popular for businesses striving to realize their designs. All in all, CNC machining services form an important part of modern manufacturing industry by providing accuracy in diversification for numerous applications.

IN: With these services tight tolerances and intricate geometries result which might be impossible or hard to copy by traditional methods of manufacture. This renders them versatile enough to be used within a variety of industries; including aerospace, automotive, consumer electronics amongst others. In addition to this they offer quick delivery terms thus making them cost effective as well as able to handle any material type selected from a wide range hence many customers prefer using them across the various business sectors whenever their innovations need actualization. Generally speaking CNC Machining Services are vital players in today’s industrial world due to their accurate nature when deployed towards different goals

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

CNC machining services can work with a wide range of materials including metals like aluminum, steel, and titanium, as well as plastics, wood, and composites.

CNC machining services offer exceptional precision, with the ability to achieve tight tolerances as low as ±0.005mm, ensuring high-quality and accurate parts.

Yes, CNC machining services excel at producing complex geometries and intricate designs, thanks to their computer-controlled precision and versatility.

Quality control in CNC machining services involves rigorous inspection processes, including dimensional checks, surface finish assessments, and material verification, ensuring adherence to specifications and standards.