Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP), is a cutting-edge additive manufacturing technology that has revolutionized the way complex objects are produced. Unlike traditional manufacturing methods that involve subtractive processes, resin 3D printing builds objects layer by layer using liquid photopolymer resin. This process enables the creation of intricate geometries, fine details, and smooth surface finishes with unparalleled precision and accuracy. Resin 3D printing has found applications in various industries, including aerospace, automotive, healthcare, and consumer goods, where high-quality, customized parts are in demand.

To achieve progress, innovation is the key and there is no better way of driving developments than using resin 3D printing. Huilichuang aims at going beyond the limits of innovation through resin 3D printing by trying out new ways for designing with materials, methods as well as applications that can be used to expand frontiers for our customers. We will continue to lead in pushing the boundaries of what resin 3D printing can do whether this means we are the first to develop new resin formulations with improved properties or exploring the most complex geometries. Working with Huilichuang allows businesses to leverage the game-changing capabilities of resin 3D printing thereby spurring innovation, shortening time-to-market and ensuring competitiveness in their sectors.

In today’s market landscape characterized by fierce competition, speediness and dexterity are necessary to stay ahead. No other printing technologies are as agile and efficient as the resin 3D printer, which is crucial in quickening the process of product development. To shorten the lifecycle of product development, Huilichuang has incorporated this technology to its rapid prototyping services. With our latest resin 3D printers, businesses can perform fast ‘what if’ analyses and design optimization aimed at validating business ideas and concepts immediately. Huilichuang’s resin 3D printing facilities are just what your new line needs or to improve on an existing one to go above any rivalry coupled with innovation.

There are numerous advantages and opportunities for customization offered by resin 3D printer that targets the specific needs of businesses in various economic sectors. Huilichuang sees that all projects have their own unique demands, thus offering a wide range of resin materials with individual properties designed according to each specific application need. Our expertise and capabilities make it possible for us to respond to client’s demands concerning structure requirements such as biocompatibility, aesthetics, or physical characteristics. The use of Huilichuang’s resin 3D printing service permits clients to customize components based on the exact specifications thereby allowing them innovate, differentiate, and become market leaders in new ways.

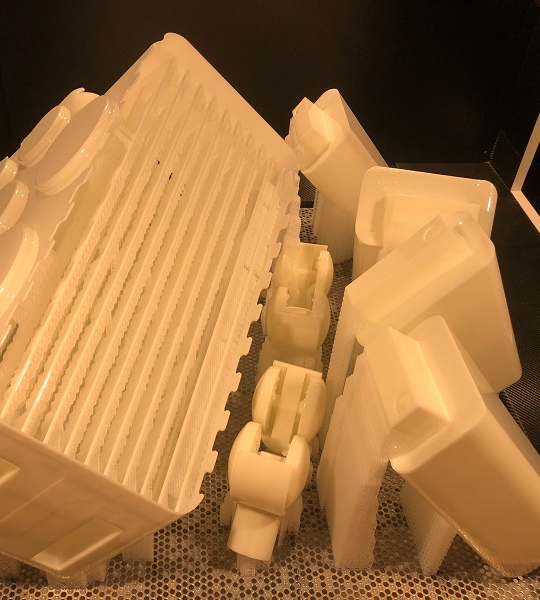

Resin 3D printing is an unmatched technology in the area of precision engineering and complex detailing. Huilichuang utilizes new resin 3D printers that can achieve accuracies and complexities that were unthinkable before. Our resin 3D printing services will always deliver superbly finished results with unmatched accuracy and consistency whether it is a finely detailed prototype, an intricate geometry or an advanced model. Every article produced by Huilichuang has been carefully crafted to meet the most demanding quality and performance standards. Thus, as a partner Huilichuang ensures trustworthiness and accuracy in every component printed using resin 3D leading to improved efficiencies in both their product lines and operations.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

Resin 3D printing offers unparalleled precision and surface finish, making it ideal for producing highly detailed, intricate objects. It also provides a wide range of material options to suit different application requirements, including strength, flexibility, and transparency.

Yes, resin 3D printing excels at handling complex geometries and fine details with exceptional accuracy. The high-resolution capabilities of resin printers allow for the production of intricate designs and delicate features that may be challenging to achieve with other manufacturing methods.

Resin 3D printing enables rapid prototyping and iterative design processes by allowing for the quick turnaround of high-quality prototypes. Its ability to produce detailed models with minimal lead times accelerates product development cycles, helping businesses bring products to market faster and more efficiently.

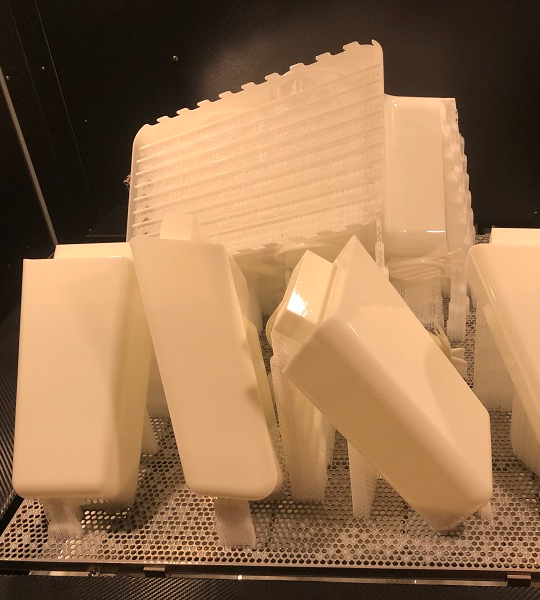

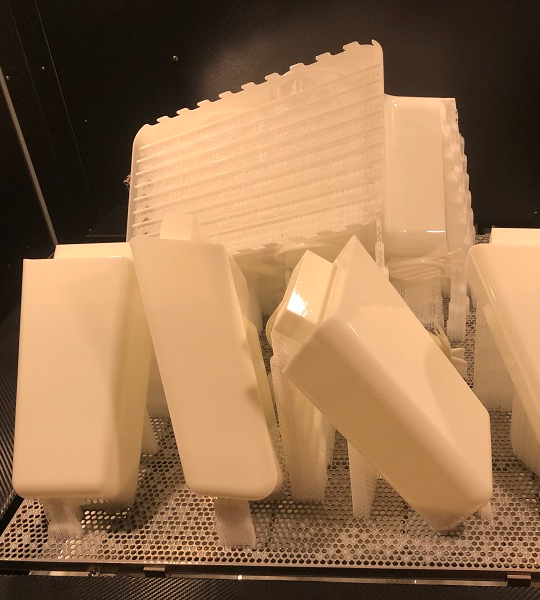

Yes, post-processing steps such as rinsing, curing, and support removal may be necessary after resin 3D printing to achieve the desired final result. These steps ensure proper curing of the printed parts and the removal of any excess resin or support structures, resulting in a finished product with smooth surface finish and precise details.