As technology continues to evolve, vacuum casting is expected to see further advancements and innovations. Future trends may include the development of new materials with enhanced properties, such as improved strength, flexibility, and biocompatibility. Additionally, advancements in mold fabrication techniques, such as additive manufacturing, may enable the production of more complex molds with faster turnaround times. Furthermore, improvements in automation and digitalization may streamline the entire vacuum casting process, reducing lead times and enhancing efficiency. Overall, the future of vacuum casting looks promising, with continued advancements driving its adoption across industries and expanding its capabilities for producing high-quality plastic parts.

Progress is triggered by a driving force and vacuum casting technology makes it an accelerator in product development innovation. Huilichuang specializes in fast prototyping services using vacuum casting to make businesses iterative, quick and productive. We have simplified procedures and modern equipment that enable us to offer fast turnarounds so that concepts can be implemented much faster than has ever been possible. Huilichuang’s quick prototype services provide the speed and flexibility needed to launch a new product or improve on an existing design, thus making your business unique among its competitors while achieving innovation.

In vacuum casting processes, quality control is of great importance to make sure each part meets the required specifications. Huilichuang incorporates strict measures for quality assurance in all stages of vacuum casting process ranging from material selection to post-processing methods. This is evident in our high-performing and long-lasting parts which are produced out of the commitment we have for quality. We conduct exhaustive reviews as well as improve procedures and invest on cutting edge machines ensuring we give our customers parts that do not compromise on quality or dependability.

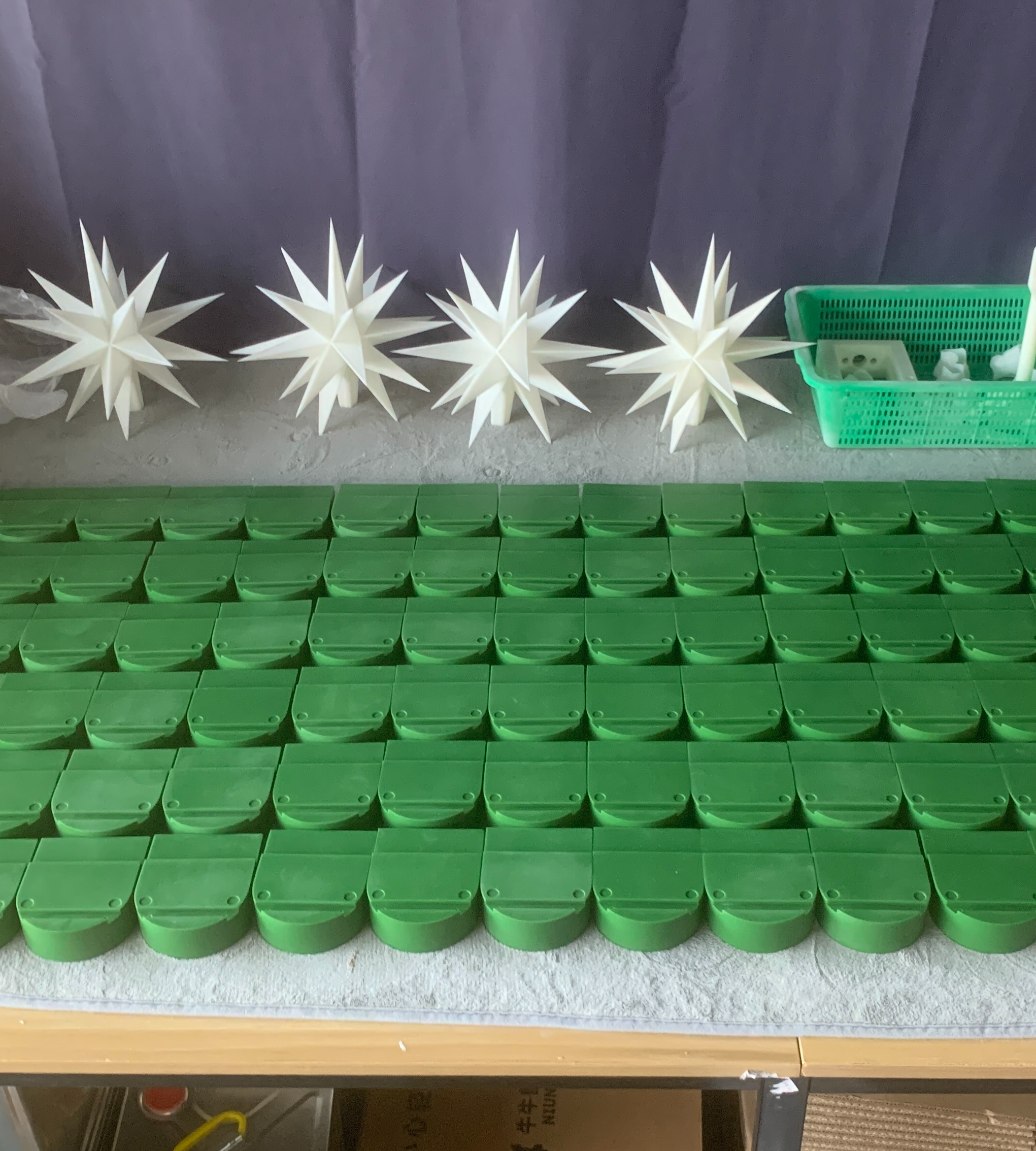

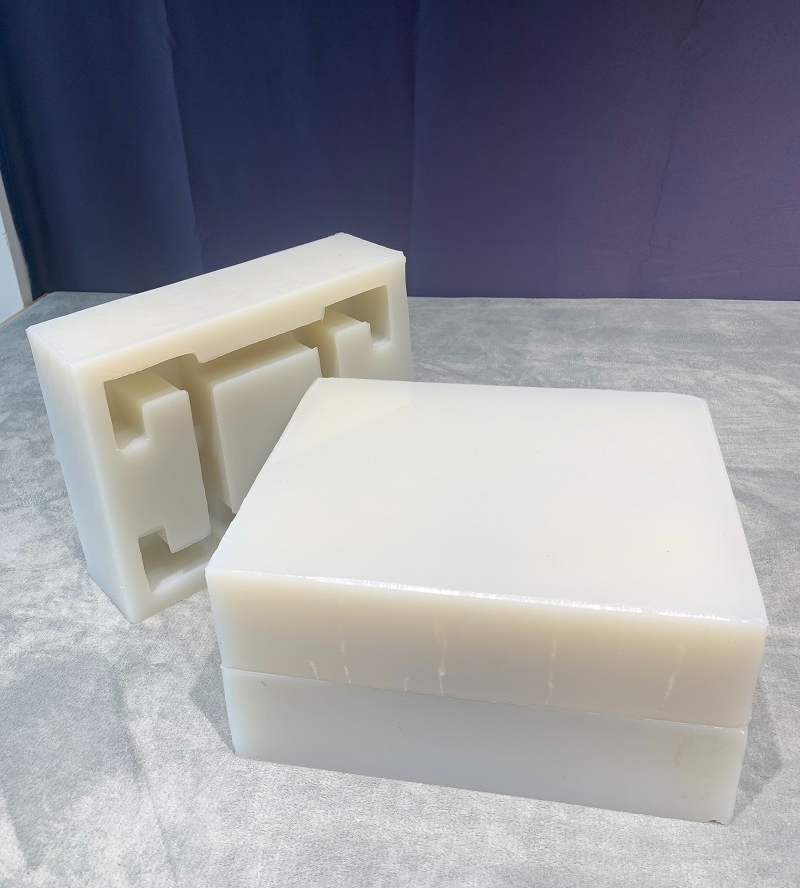

Since vacuum casting technology is better than any other when it comes to things like accuracy in engineering, and fine details, precision engineering and intricate detailing are its strong points. We at Huilichuang have employed vacuum casting to attain higher quality levels of precision and detail expected. Our professionals use modern methods like CNC machining or 3D printing to manufacture their master patterns very carefully. The most intricate details of these master patterns are captured with the highest degree of accuracy by encasing them using top-notch silicone molds. In conclusion, such parts exhibit exceptional characteristics like surface finish, dimensional accuracy as well as complicated details which meet all the necessary quality standards to deliver the best performance.

Core value at Huilichuang includes sustainability, and for this reason environmental responsibility is paramount in all our operations including vacuum casting. By optimizing material usage, minimizing waste generation and observing energy efficient practices, we aim to reduce our environmental impact. Furthermore, we have eco-friendly casting materials and continually seek new ideas that will make our operations more sustainable. Trust that your project of vacuum casting with Huilichuang observes the environment strictly and hopes for a greener world for all generations.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

Vacuum casting offers lower tooling costs, rapid turnaround times, and the ability to produce small batch sizes economically. Additionally, it accommodates intricate geometries and complex part designs effectively.

Yes, vacuum casting supports a wide range of casting materials, including polyurethanes, epoxies, and silicones, allowing for the production of parts with varying mechanical, thermal, and aesthetic properties.

Vacuum casting projects typically have a turnaround time of days to weeks, depending on factors such as part complexity, batch size, and material selection. This rapid turnaround enables quick iteration and validation of designs.

Vacuum casting utilizes flexible silicone molds, which accurately replicate the geometry of master patterns, ensuring precise reproduction of intricate details and complex features in the final parts.