Huilichuang is a leading manufacturer providing a comprehensive range of cutting-edge products and services to meet the diverse needs of our clients. Our extensive product portfolio includes:

1. 3D Printing FDM Service: Fused Deposition Modeling (FDM) is an additive manufacturing technique that constructs objects layer by layer using thermoplastic materials. FDM technology is crucial for rapid prototyping, functional testing, and concept modeling due to its cost-effectiveness and versatility.

2. 3D Printing SLA Service: Stereolithography (SLA) is a resin-based 3D printing process that employs a UV laser to solidify liquid resin into precise layers. SLA technology is essential for producing high-resolution prototypes, intricate models, and investment casting patterns with exceptional detail and accuracy.

3. 3D Printing SLS Service: Selective Laser Sintering (SLS) is a powder-based additive manufacturing method that uses a laser to fuse powdered material into solid layers. SLS technology is indispensable for creating functional prototypes, end-use parts, and complex geometries without the need for support structures.

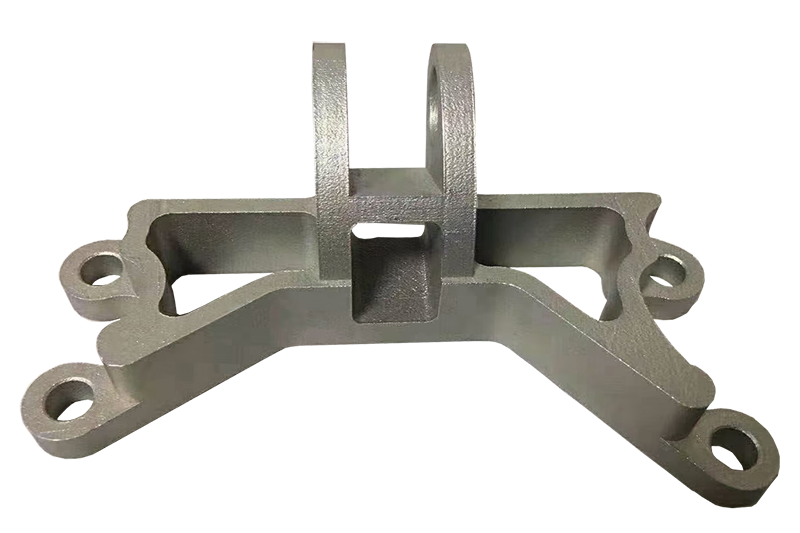

4. Metal 3D Printing: Metal 3D printing, also known as additive manufacturing, utilizes metal powders to produce durable and precise metal components. Metal 3D printing is vital for aerospace, automotive, and medical industries for manufacturing complex parts with superior mechanical properties.

5. Plastic 3D Printing: Plastic 3D printing encompasses various techniques such as FDM, SLA, and SLS to produce plastic parts with different characteristics. Plastic 3D printing is essential for rapid prototyping, product development, and low-volume manufacturing across various industries.

6. Resin 3D Printing: Resin 3D printing employs liquid resin materials cured by UV light to create detailed parts with smooth surface finishes. Resin 3D printing is critical for producing intricate models, dental appliances, and jewelry prototypes with exceptional precision.

7. Nylon 3D Printing: Nylon 3D printing utilizes nylon-based materials to fabricate parts with high strength, flexibility, and durability. Nylon 3D printing is significant in engineering applications, including functional prototypes, tooling, and end-use parts requiring robust mechanical properties.

8. Vacuum Casting: Vacuum casting is a rapid prototyping and low-volume manufacturing process that duplicates detailed parts using silicone molds. Vacuum casting is vital for producing small batches of high-quality plastic parts with complex geometries and fine surface finishes.

9. CNC Machining Services: CNC machining is a subtractive manufacturing method that employs computer-controlled machines to remove material from solid blocks to create precise parts. CNC machining is essential for producing metal and plastic components with tight tolerances and intricate features.

At Huilichuang, we understand the importance of these products and services in driving innovation and meeting the evolving demands of the manufacturing industry. Our commitment to excellence ensures that we deliver top-quality solutions to our clients, empowering them to turn their ideas into reality with efficiency and precision.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES