Quality assurance is a paramount concern in metal 3D printing to ensure the reliability and performance of the manufactured parts. Rigorous testing and inspection procedures are employed throughout the production process to verify dimensional accuracy, material integrity, and mechanical properties. Non-destructive testing methods, such as X-ray inspection and ultrasonic testing, are commonly utilized to detect defects and ensure the structural integrity of the components. Metallurgical analysis and mechanical testing further validate the material properties and performance characteristics of the finished parts, ensuring they meet stringent quality standards.

At Huilichuang, quality is paramount in every aspect of our manufacturing process, and metal 3D printing is no exception. We employ rigorous quality control measures and inspection techniques to ensure that each metal 3D printed component meets the highest standards of dimensional accuracy, material integrity, and mechanical performance. From initial design validation to final inspection, we uphold the utmost quality and reliability in every metal 3D printed part we produce. The quality assurance process begins with careful design validation and simulation to optimize part geometry, orientation, and support structures for metal 3D printing. Once the printing process is complete, each part undergoes thorough inspection and testing to verify dimensional accuracy, surface finish, and material properties. Non-destructive testing methods, such as X-ray inspection and ultrasonic testing, are commonly employed to detect defects and ensure the structural integrity of the components. Additionally, metallurgical analysis and mechanical testing further validate the material properties and performance characteristics of the finished parts.

As a forward-thinking production manufacturer, Huilichuang leverages metal 3D printing to drive innovation and push the boundaries of what's possible in manufacturing. By collaborating with customers, research institutions, and industry partners, we explore new applications, materials, and processes to unlock new opportunities and address emerging challenges in diverse industries, from aerospace and automotive to healthcare and beyond. Metal 3D printing enables Huilichuang to push the boundaries of design, material science, and manufacturing technology, driving innovation and accelerating product development across industries. Whether it's developing lightweight aerospace components, biocompatible medical implants, or high-performance automotive parts, metal 3D printing offers limitless possibilities for innovation and advancement. By embracing metal 3D printing, Huilichuang is poised to lead the way in shaping the future of manufacturing and driving positive change across industries.

Another key advantage of metal 3D printing is its ability to accelerate product development and reduce time-to-market. Traditional product development cycles often involve lengthy lead times and high costs associated with tooling, machining, and prototyping. metal 3D printing streamlines the product development process by enabling rapid prototyping, iteration, and validation of designs. With Huilichuang's advanced metal 3D printing capabilities, we can quickly produce functional prototypes, test designs, and iterate on product concepts, allowing our customers to bring innovative products to market faster and stay ahead of the competition. Moreover, metal 3D printing facilitates agile manufacturing processes that can adapt to changing market demands and customer requirements. By eliminating the need for tooling and reducing setup times, metal 3D printing enables on-demand production of custom and low-volume parts without the constraints of traditional manufacturing. This agility in manufacturing gives Huilichuang a competitive edge, allowing us to respond quickly to customer needs, reduce inventory costs, and optimize supply chain management. As a result, our customers can benefit from reduced lead times, lower production costs, and faster time-to-market for their products.

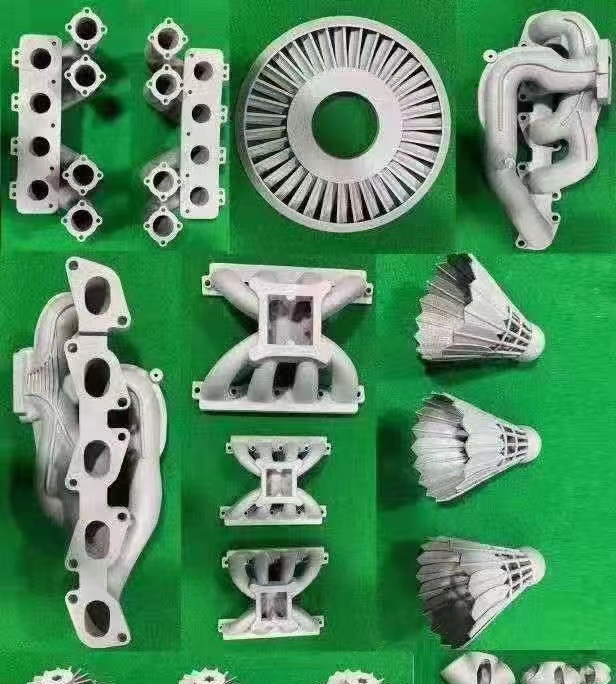

One of the most significant advantages of metal 3D printing is its ability to enhance design flexibility and complexity. Unlike traditional manufacturing methods, which are often limited by the constraints of machining and tooling, metal 3D printing offers designers unparalleled freedom to create intricate geometries and complex structures. By selectively melting metal powder layer by layer according to digital designs, Huilichuang can produce components with internal channels, lattice structures, and organic shapes that optimize performance and functionality. This flexibility in design allows us to push the boundaries of what's possible, delivering innovative solutions tailored to the unique needs of each application and industry. Moreover, metal 3D printing enables the integration of multiple components into a single printed part, reducing the need for assembly and simplifying the overall manufacturing process. By consolidating parts and eliminating the constraints of traditional manufacturing, designers can optimize designs for weight reduction, material usage, and performance. Whether it's creating lightweight aerospace components, intricate medical implants, or high-performance automotive parts, metal 3D printing empowers designers to explore new possibilities and innovate without limitations.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

Metal 3D printing supports a wide range of materials including titanium, stainless steel, aluminum, cobalt-chrome alloys, and more. Each material offers unique mechanical properties suitable for specific applications, ensuring versatility and performance.

Post-processing for metal 3D printed parts may include heat treatment, machining, surface finishing, and inspection to achieve desired mechanical properties and surface quality. These steps ensure the final parts meet performance and aesthetic standards.

Metal 3D printing offers advantages such as the ability to produce complex geometries, reduced material waste, and customization options not feasible with traditional methods. It also enables rapid prototyping, on-demand production, and lightweight yet durable components.

While initial investments in metal 3D printing equipment can be higher, the overall cost can be competitive due to reduced material waste, lower tooling costs for complex geometries, and decreased lead times. Cost-effectiveness varies depending on the part complexity, volume, and material selection.