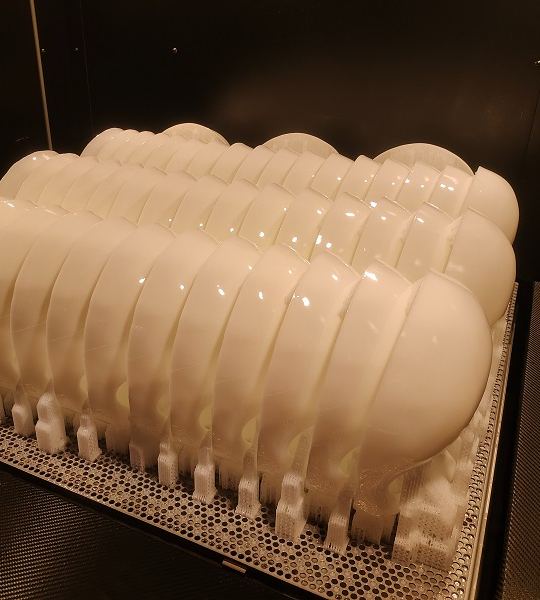

3D Printing SLA (Stereolithography) Service represents a cutting-edge additive manufacturing technology that utilizes ultraviolet (UV) light to cure liquid photopolymer resin layer by layer, producing highly detailed and precise parts. This advanced printing process enables the creation of complex geometries with exceptional resolution and surface finish, making it ideal for various applications across industries such as aerospace, automotive, healthcare, and consumer goods. With its ability to produce intricate parts with fine details, 3D printing SLA service offers unparalleled capabilities for prototyping, product development, and low-volume production.

There is no need for the price of creativity to be that high: we are dedicated to supplying cost-effective solutions that maintain standards at Huilichuang. Our 3D printing SLA service offers the best value in terms of reducing production costs and enhancing returns for companies. We apply additive manufacturing methods to minimize waste materials; hence you can access first-class parts at lower prices. Therefore, by our side during manufacturing, a cheaper revolution can be realized with better performance and quality. Lastly, our commitment to affordable modes of delivering answers ensures full exploitation of the investment on additive manufacturing.

Additive manufacturing is the future of manufacturing and Huilichuang is at the vanguard of this revolution with our ground-breaking 3D printing SLA service. We’re continuously challenging the limits of what can be done, exploring new materials, methods, and applications to change the face of this industry. Partner with us; let’s embrace tomorrow’s production technology in our 3D printing SLA service. At Huilichuang, we realize that Tomorrow is today! We are transforming manufacturing industry by building innovative solutions that will shape the future one part after another. Come on board as we take a life-changing journey through additive manufacturing aided by Huilichuang.

Of late, Huilichuang has emerged as a renowned supplier of 3D printing SLA services in the manufacturing sector. We have spent many years and applied cutting-edge technological innovations to ensure our customers get fine-tuned machines parts. Through this service, we offer unmatched truth regarding details thus giving assurance to businesses when making complicated objects for various purposes. For companies that want to advance their manufacturing abilities, Huilichuang is the leading choice since it highly values quality and creativity.

The most important thing in our 3D printing SLA service is quality. We do not compromise a thing from the first design to the final production process, maintaining high standards for accuracy and correctness. Our committed group checks every piece closely with strict quality control systems that ensure uniformity and precision. When dealing with Huilichuang you are assured of good hands on your projects because it always gives good results on countless occasions. By emphasizing quality control at each step of the production process, we guarantee that clients get exactly what they ordered or even better than they expected.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

3D printing SLA service stands out for its high resolution and exceptional surface finish, making it ideal for producing intricate and detailed parts with precision.

Parts produced by 3D printing SLA service often exhibit superior accuracy, as the process allows for the creation of complex geometries with minimal distortion or deviation from design specifications.

Turnaround times for orders with 3D printing SLA service vary depending on factors such as part size, complexity, and quantity, but generally offer fast lead times compared to traditional manufacturing methods.

Yes, 3D printing SLA service supports a variety of resin materials, including standard, engineering, and specialty resins, enabling versatility in meeting diverse application requirements.