While metal 3D printing offers numerous advantages over traditional manufacturing methods, such as increased design freedom and reduced lead times, it also presents unique challenges, particularly in post-processing. After the printing process, metal 3D printed parts often require additional finishing steps to achieve the desired surface finish and dimensional accuracy. Common post-processing techniques include heat treatment to improve material properties, CNC machining to refine critical features, and surface finishing processes like polishing or coating to enhance aesthetics and functionality. These post-processing steps are essential to meet the stringent requirements of demanding applications across various industries.

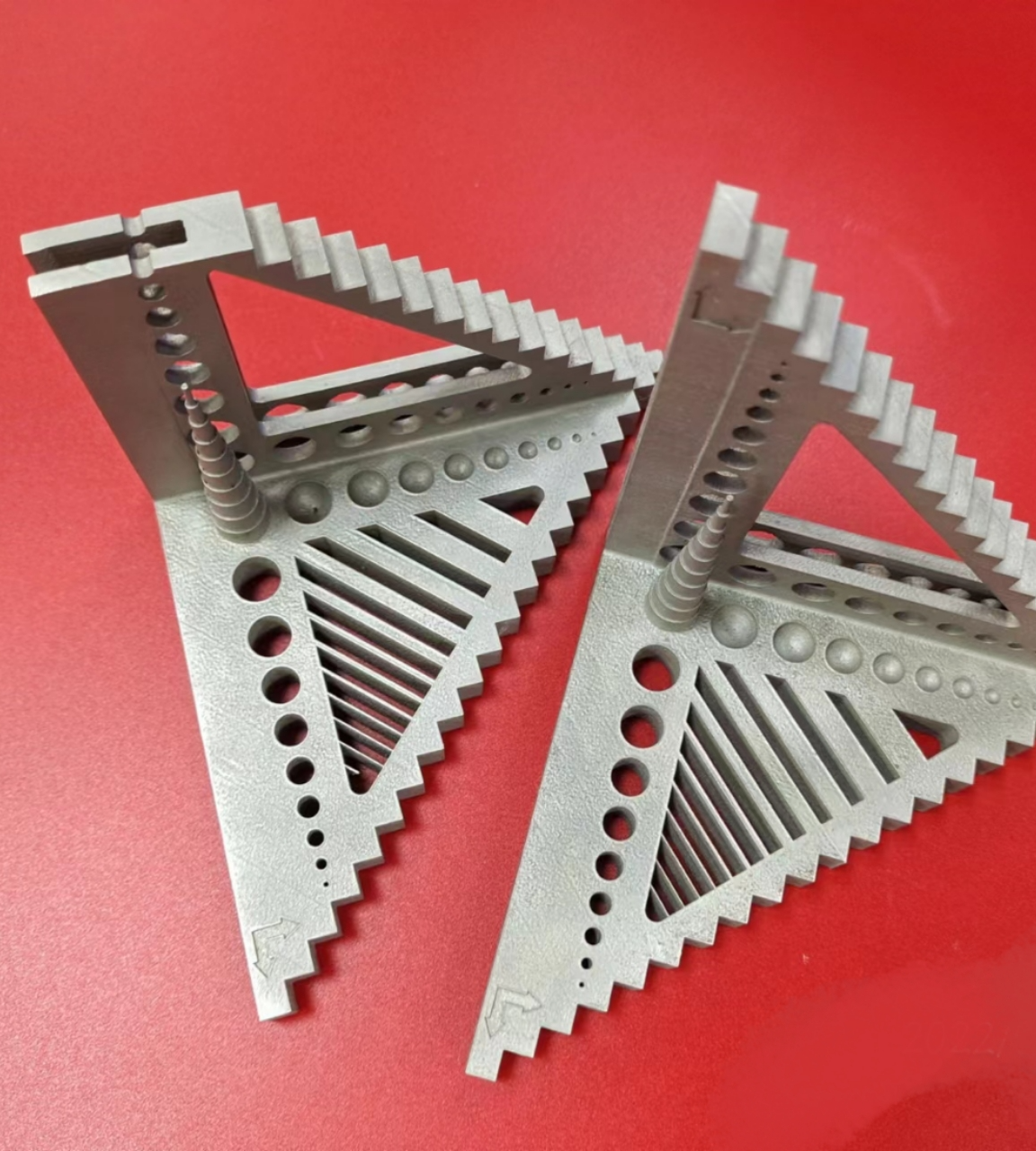

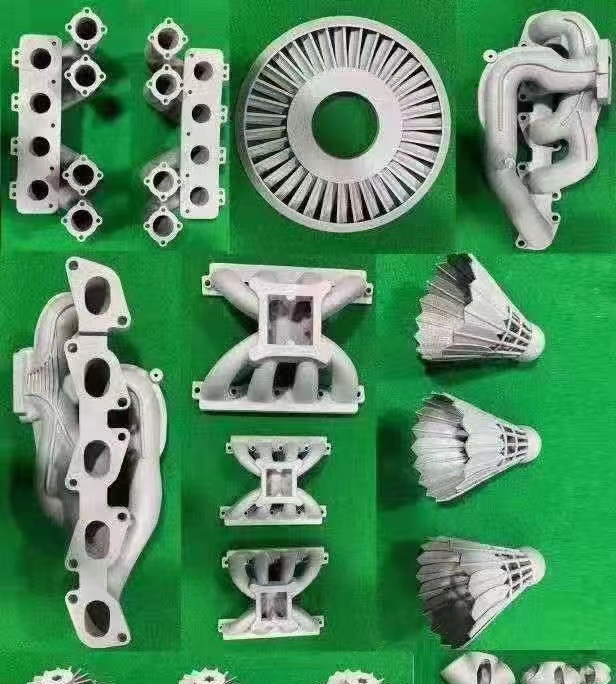

Metal 3D printing offers a significant advantage of increasing flexibility and complexity in design. While traditional manufacturing methods are often restricted by machining and tooling, metal 3D printing enables unlimited freedom for designers to produce complex structures and intricate geometries. Huilichuang can make parts with internal channels, lattice structures, and organic shapes that are optimized for performance and functionality by selectively melting metal powder according to digital designs one layer after another. This allows us to go beyond the limits of what is possible, producing new solutions that suit each application or industry requirement uniquely. Moreover, multiple components can be merged into one printed part with metal 3D printing thereby reducing assembly requirements and simplifying the overall production process. Designers can therefore consolidate parts using additive manufacturing rather than traditional production methods thereby allowing them optimize designs as per weight savings, material utilization rates and functional outcomes. Metal 3D printing makes it possible to design lightweight aerospace components, complex medical implants or high-performance automotive parts without limitation.

Apart from the fact that it boosts design flexibility, metal 3D printing allows for considerable efficiency in terms of material usage and sustainability. As such, traditional manufacturing approaches tend to generate a lot of waste when subtractive techniques involving processes like machining, milling, and cutting are applied. Contrastingly, material is only put where it ought to be placed during the additive process thereby reducing wastage and cutting down on consumption. Huilichuang could optimize material usage by layering metal powder and selectively melting it through high-powered lasers thus enhancing eco-friendliness in our production methods. On top of this, metal 3D printing has facilitated the use of superior alloys and advanced materials as mechanical properties. Long list of materials available such as titanium, stainless steel, aluminum, nickel alloys or cobalt-chrome alloys helps designers opt for the most fitting one for every application so that it can perform well enough all along with reliability assured at last. Moreover, recycling surplus metal powder supports environmentally soundness not only in relation to the company’s mission on environmental responsibility as an element of its sustainable development approach but also about a specific aspect of its corporate culture promoting nature-friendly actions and attitudes concerned with social life.

In Huilichuang, quality is highly considered in all aspects of our manufacturing process including metal 3D printing. We employ strict quality control criteria and inspection techniques so that every metal 3D printed component can adhere to the highest levels of dimensional accuracy, material integrity and mechanical performance. From the beginning of design validation to final inspection, each part we produce has the highest level of quality and reliability among all other metal 3D printed parts. The quality assurance process begins with careful design validation and simulation to optimize part geometry, orientation, and support structures for metal 3D printing. After completion of the printing process, each part undergoes comprehensive inspection and testing to check dimensional accuracy, surface finish, and material properties. Besides defect identification for structural integrity using non-destructive testing techniques such as x-ray examination or ultrasonic testing; metallurgical analysis as well as mechanical tests also aid in validating the material properties and performance characteristics of these parts when they have been completed.

By embracing metal 3D printing, it is our belief that Huilichuang has demonstrated commitment to quality at all times with the aim of satisfying its customers greatly and becoming the best and outstanding. As a result, we ensure that we are up to date with the latest technology, spending also on equipment as well as hiring skilled employees in order that we remain on par with everything happening in metal 3D printing industry thereby producing excellent goods and services that go beyond client’s expectations. We are one of the most recognized companies which deal with metal 3D printing since there is no such thing like us in terms of quality, innovation and customer focused approach. The possibilities are limitless when we continually seek to break down barriers even further by getting involved in new materials, processes and applications which can bring about change towards a brighter future for manufacturing as well. By maintaining an unwavering commitment to delivering top-notch products & services along with ensuring high level customer satisfaction, Huilichuang aims to be an innovator in metal 3D printing across various industries.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

Metal 3D printing supports a wide range of materials including titanium, stainless steel, aluminum, cobalt-chrome alloys, and more. Each material offers unique mechanical properties suitable for specific applications, ensuring versatility and performance.

Post-processing for metal 3D printed parts may include heat treatment, machining, surface finishing, and inspection to achieve desired mechanical properties and surface quality. These steps ensure the final parts meet performance and aesthetic standards.

Metal 3D printing offers advantages such as the ability to produce complex geometries, reduced material waste, and customization options not feasible with traditional methods. It also enables rapid prototyping, on-demand production, and lightweight yet durable components.

While initial investments in metal 3D printing equipment can be higher, the overall cost can be competitive due to reduced material waste, lower tooling costs for complex geometries, and decreased lead times. Cost-effectiveness varies depending on the part complexity, volume, and material selection.