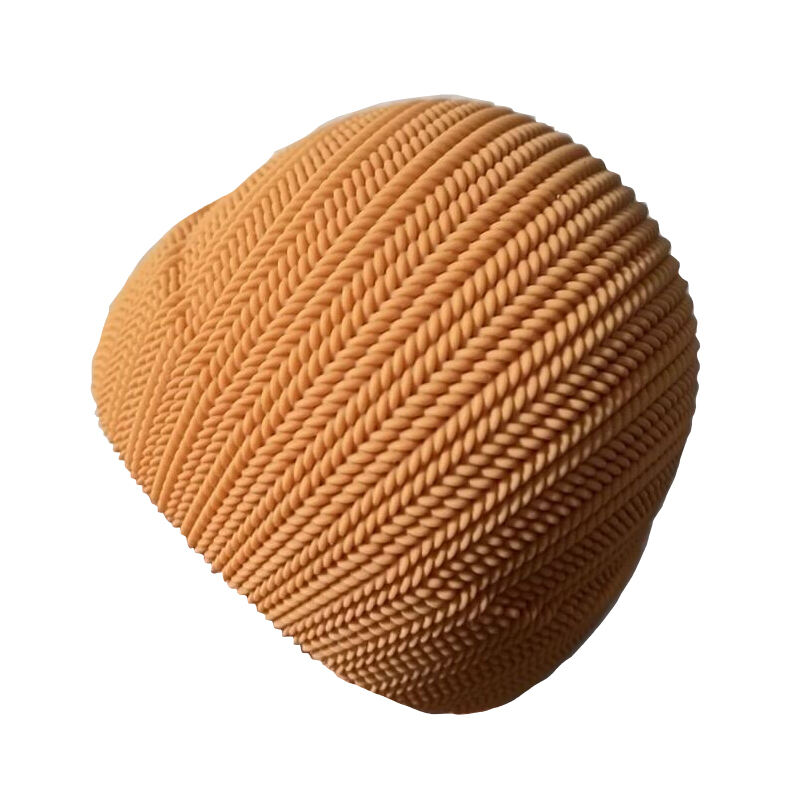

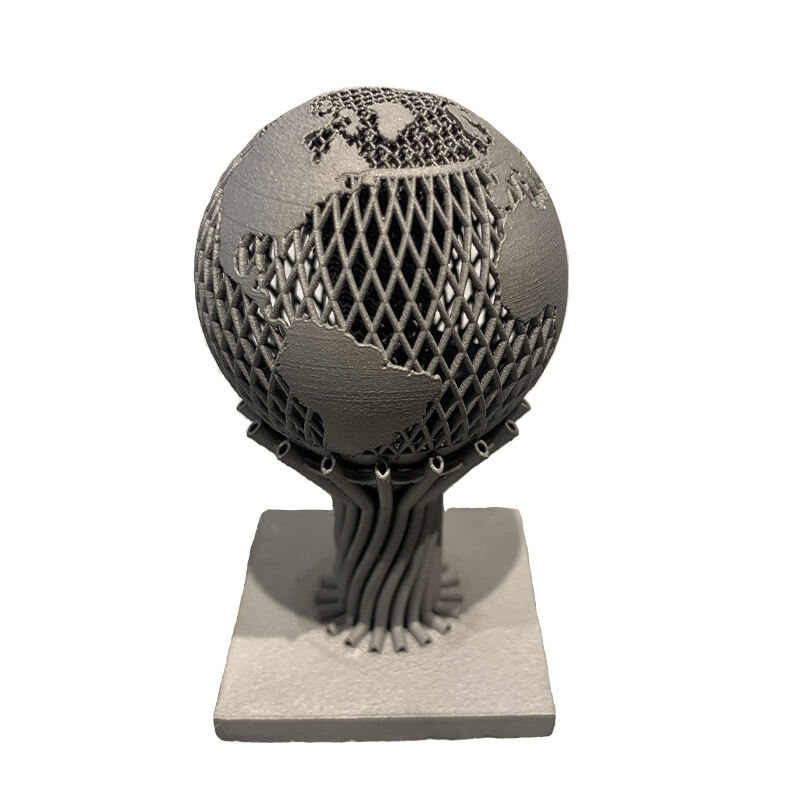

Soft Rubber TPU

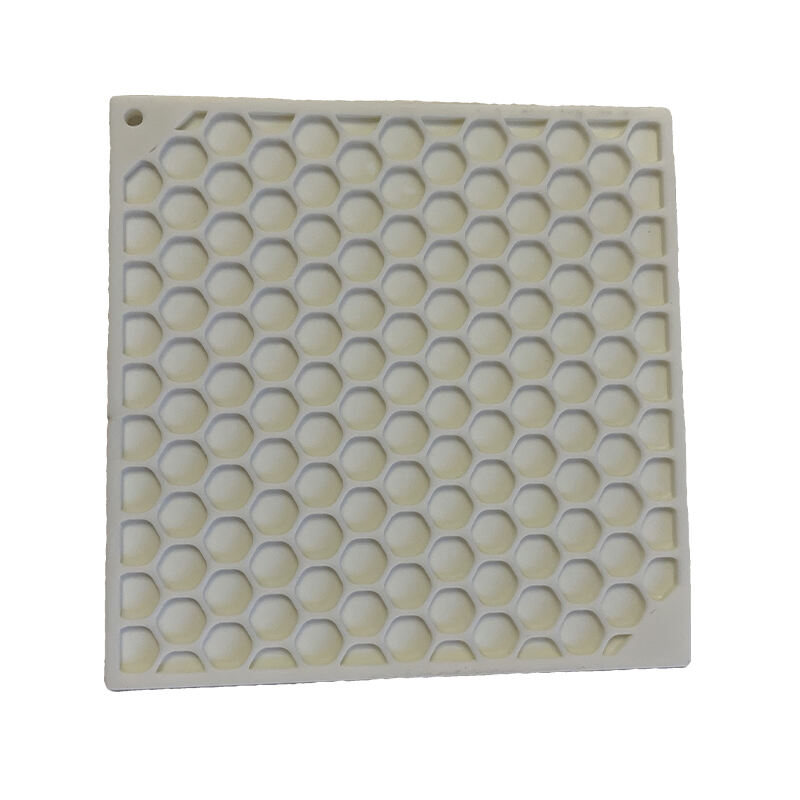

Products Of Complex Mold are custom-made plastic parts that can have intricate shapes and sizes. They are created by injecting molten resin into metal molds with advanced features.

- Overview

- Parameter

- Inquiry

- Related Products

Complex Mold is a high-performance material designed specifically for 3D printing with excellent heat, abrasion, chemical resistance and strength. Complex Mold can be used to manufacture complex geometries such as molds, fixtures, gears, bearings, etc. without post-processing or machining. Complex Mold can also be compounded with other materials such as metal, ceramic or rubber to achieve greater functionality and aesthetics.

Complex Mold material series includes the following types:

Complex Mold PA: Nylon-based material with high strength, high toughness and high heat resistance, suitable for high temperature, high pressure or high speed applications such as automotive, aerospace or mechanical fields.

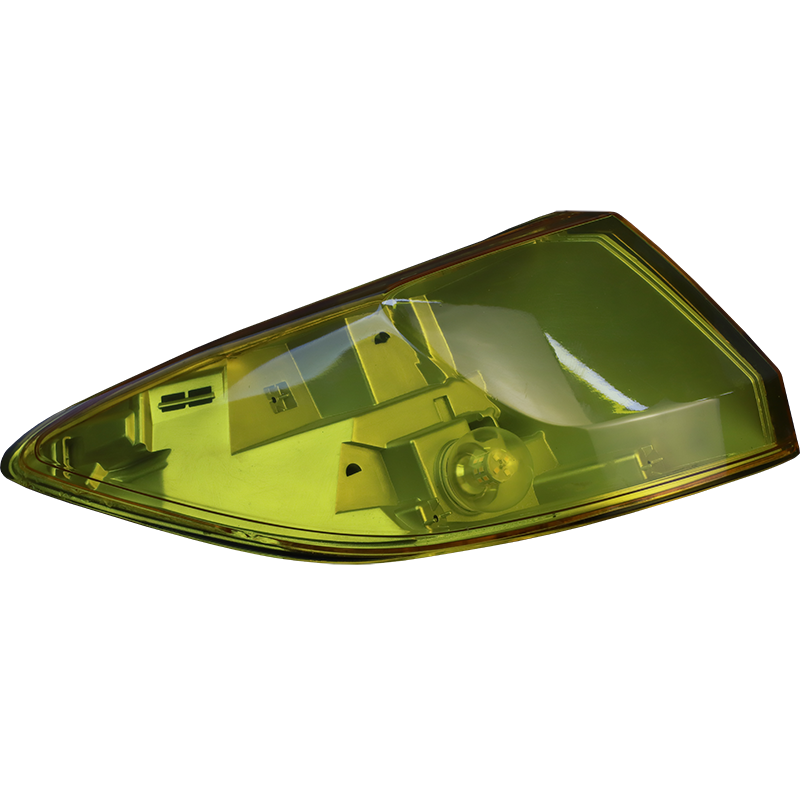

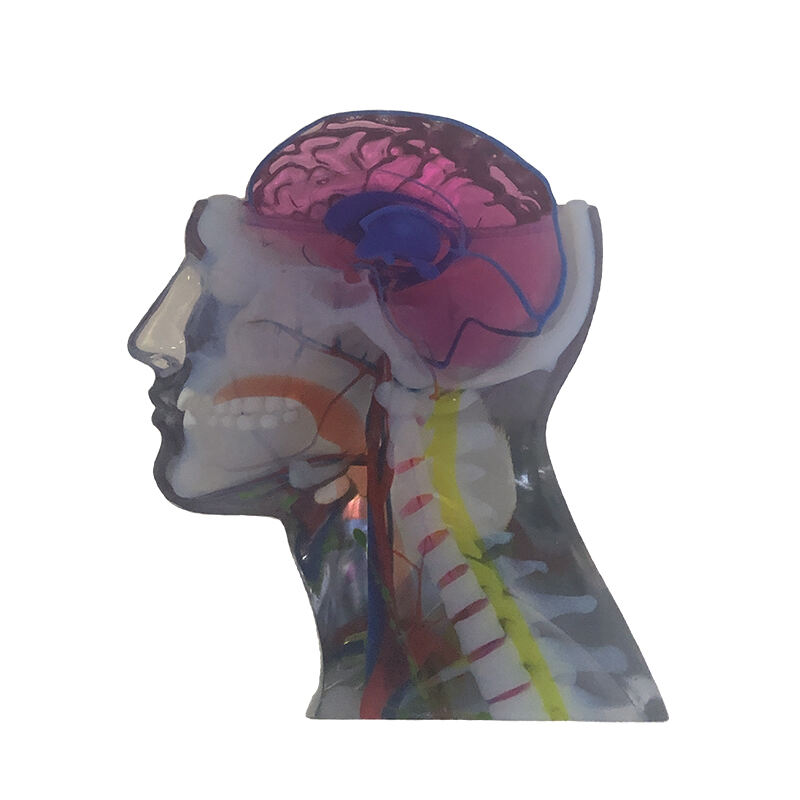

Complex Mold PC: Polycarbonate-based material with high transparency, high impact resistance and high abrasion resistance, suitable for applications requiring optical quality or weather resistance, such as medical, lighting or consumer electronics.

Complex Mold PEEK: Polyetheretherketone-based material with ultra-high thermal resistance, chemical resistance and biocompatibility, suitable for applications requiring extreme performance or hygiene requirements, such as medical implants, food processing or petroleum chemical industry.

Complex Mold TPU: Thermoplastic polyurethane-based material with high flexibility, elasticity and oil resistance, suitable for applications that require softness or shock resistance, such as in sports shoes, protective gear or seals.

3D printing products from the Complex Mold material series offer the following advantages:

High precision: Complex Mold materials can be processed through 3D printing technology of powder bed fusion (PBF) or powder bed bonding (PBA) to achieve an accuracy of up to 0.05 mm to meet various delicate design requirements.

Stable quality: Complex Mold materials undergo strict quality control and testing to ensure consistent physical and chemical properties and avoid quality problems caused by batch or environmental changes.

Cost Savings: Complex Mold materials can print the required shape directly from the 3D model without the need for additional molds or cutting tools, reducing material waste and labor costs, and improving production efficiency and flexibility.

The 3D printing products of the Complex Mold material series are an innovative solution that can meet the different needs of various industries and bring higher value and competitiveness to your projects.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES